Project Portfolio

Recent Projects in the Field

Our expert crews are rigging complex loads, transporting and operating equipment and bringing innovative projects to life throughout the region every day.

Heavy Rigging – Industrial Manufacturing

It’s not everyday your business receives a new 96,000lb CNC machine. Clark was called upon to move the new machine from from its delivery and install it within the customer’s building.

Solution Based Services – Telecom

“How are we going to get those under there?” That is what Clark Rigging’s customer asked. Clark is committed to finding a solution that will meet the needs of its customers. In this specific project: Clark designed & fabricated a custom lifting beam to reach under the bowl of a water tank to install telecommunication […]

University at Buffalo – The Right Equipment & the Right People

- University at Buffalo

The electrical upgrades on this project required the full range of Clark’s equipment from big to small. Meanwhile Clark’s experienced crane & rigging crews executed both phases of the project flawlessly.

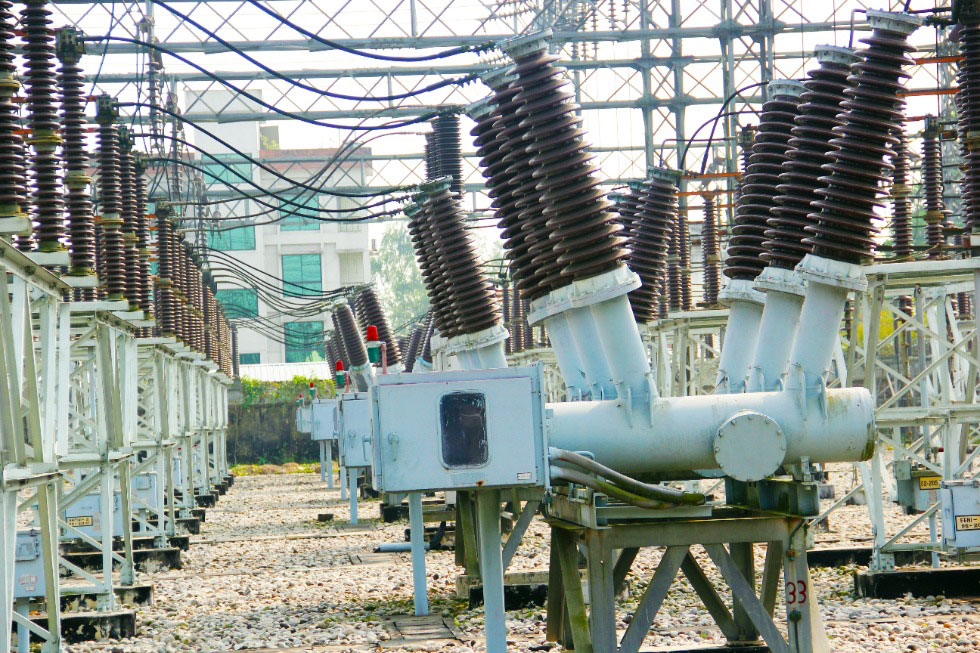

Utility Trust

- New York

The lights must stay on! Clark is continuously trusted to provide a reliable service for one of New York’s primary electrical utilities. There is not a week that goes by where Clark is not working in a substation across the state. Working in these in environments requires the utmost attention to safety. Safety through planning […]

Crane, Rigging and Heavy Hauling from New York to Pennsylvania

- New York & Pennsylvania

Clark provided a single source solution to move (2) large natural gas digestors systems from New York to Pennsylvania. The project consisted of : -Crane & Rigging services for loading -Transportation

Precast Wall Panel Erection – Niagara Falls NY

- Niagara Falls, NY

Clark working alongside their consistent customer mobilized one of their Link-Belt 298 crawler cranes to assist in setting precast concrete wall panels. The project consisted of developing a crane plan & coordinating safety- efficiency with the general contractor to ensure a successful project. The project consisted of setting 500 panels upwards of 50,000lbs ea. Clark’s […]

Buffalo State College – Classroom Upgrades

- Buffalo NY

Clark Rigging & Rental Corp. was contracted by one of their long time mechanical partners to assist in installing (3) modular indoor air handling units. The project utilized of all of Clark Rigging’s services:

Alro Steel

- May 2024

- Rochester, NY

Clark Rigging was recently contracted to provide experienced project management, specialized equipment, skilled labor, and creative logistics to offload multiple oversized co-generation boiler units from rail-cars, then transport them all to Kodak Park in Rochester, NY. Two of Clark Rigging’s 400t Terex AC 350/6 cranes worked in unison to safely transfer the bulky units from […]

RED Rochester

- June 2024

- Rochester, NY

Two of Clark Rigging’s newest cranes recently teamed up on a project in Rochester, NY to offload and assemble a co-generation boiler for RED Rochester. Clark Rigging’s Liebherr LR 1300.1 SX and Tadano AC 7.450-1 cranes were chosen for the delicate work to safely set the immense units in place.

JW Danforth NFTA Building Chiller

- February 3, 2024

- Buffalo, NY

25,000 lb. ChillerReceive, Store, Deliver, & Set110′ Up122′ RadiusCrane configured with 210′ MB and Superlift

Nucor Steel Transformer Changeover

- Winter, 2023

- Auburn, NY

An urgent situation recently unfolded at Nucor Steel when an electrical transformer suddenly failed sending most of the facility into darkness. The operation of this 150,000 lb. transformer is critically important in keeping the Auburn, NY facility’s furnaces functional 24 hours a day, 7 days a week. Clark Rigging’s General Foreman Gunter Minges received the urgent […]

Cerrone North Trail Face Headwall Removal and Shoreline Stabilization

- Spring, 2023

- Lewiston, NY

The New York Power Authority’s Robert Moses Plant is one of the largest hydro-electric generating facilities in the U.S. The facility moves 25 turbines with 748,000 gallons of water per second to produce a maximum voltage of 2.6 million kilowatts of electricity. This electricity supports communities across the North-East. Since its construction in 1961 Clark has […]

Materials Handling of Wind Tower Components at the Port of Oswego

- Fall, 2022

- Oswego, NY

Clark Rigging was recently contracted to assist with the ship offloading, handling, and staging of large wind tower components at the Port of Oswego. After much consideration, Clark Rigging’s experienced Project Manager, Mike Dombroski determined the use of crawler cranes to be most efficient for the majority of this project. Clark dispatched a total of […]

Wind Turbine Repair and Rebuilt Assist for HARBEC

- Summer, 2022

- Ontario, NY

HARBEC, a well known sustainable manufacturing company located along the NY-104 corridor in Ontario, NY, is widely recognized in their efforts to minimize negative environmental impacts, and conserve energy and earth’s natural resources. HARBEC recently called on Clark Rigging to assist in the repair and rebuilding of one of their two onsite wind turbines. These turbines […]

Clark Companies Annual Safety Meeting 2022

- Winter, 2022

Clark Companies Annual Safety Meeting 2022Each year Clark Companies puts on a mandatory safety meeting for its employees. The meeting consists of a presentation/discussion done by a guest speaker or speakers on a certain safety topic chosen by Clark Companies management. Following the presentation Clark Companies’ Safety Manager presents the company safety statistics from the […]

Clark’s newest cranes working at Western New York Energy Plant

- Medina, NY

- Fall, 2021

Western New York Energy is one of the largest biofuel producers in the Northeast, and is currently undergoing a multi-million dollar expansion at it’s production plant in Medina, NY. One of Clark Rigging’s newest cranes to enter the fleet, a Link-Belt 298 HSL Series-2 Lattice Boom Crawler Crane was recently dispatched to the processing plant to […]

Clark’s Hydra-Slide skidding system used to replace power transformers

- Summer, 2021

One of Clark Rigging’s newest pieces of equipment was recently utilized to perform a series of transformer replacements at several electrical substations throughout Western New York. These electrical substations had failed transformers located inside a roofed bay enclosure, or directly under live overhead power lines which limited the use of a crane to move them […]

Clark’s newest cranes used for Syracuse Carrier Dome renovation

- Summer, 2020

- Syracuse, NY

Several of Clark Rigging’s newest cranes recently teamed up on various projects at Syracuse University’s Carrier Dome in Syracuse, NY. The facility is currently undergoing a multi-million dollar renovation project on improvements that will include a permanent roof, a vertically hung scoreboard, air conditioning and other amenities. Clark Rigging has dispatched several cranes to assist […]